Our Work

OD, ID, and Surface Grinding

Our tool and die facility would not be whole without our OD/ID and Surface Grinding Department. While some think these operations are simple, they are actually just as important as any of the other manufacturing areas. Nearly every item manufactured goes through this department and our staff operating the equipment are working with the same precision as any other department.

Conventional Sinker EDM

Whether working on a miniscule scale with electrical contacts or larger surfaces with multiple components, our employees are trained to craft the highest-quality finish possible. The smaller the recast layer is, the greater the amount of detail on the finished component – this helps to avoid distortion during the final polishing process.

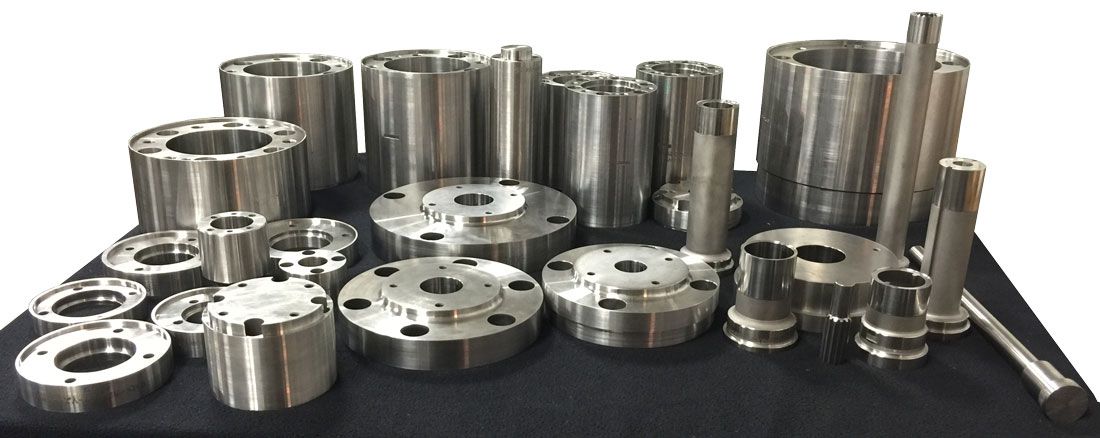

Powder Compaction Tooling

We create die sets as well as their support tooling, and also perform reface/repair on compaction tooling. Producing the tooling is only the beginning, we also pride ourselves on our ability to deliver on time.

Precision Machining

Using our CNC machining equipment we are able to cut shaped tooling. Our six lathes range in size allowing high precision, including a swing capacity of up to 20 inches. We also heat treat all of the pieces produced using one of the three box furnaces in our facility.

Inspection & Measuring

Using advanced inspection and measuring tools we are able to ensure that all of the tools we make conform to the values required by that part’s design.